In China

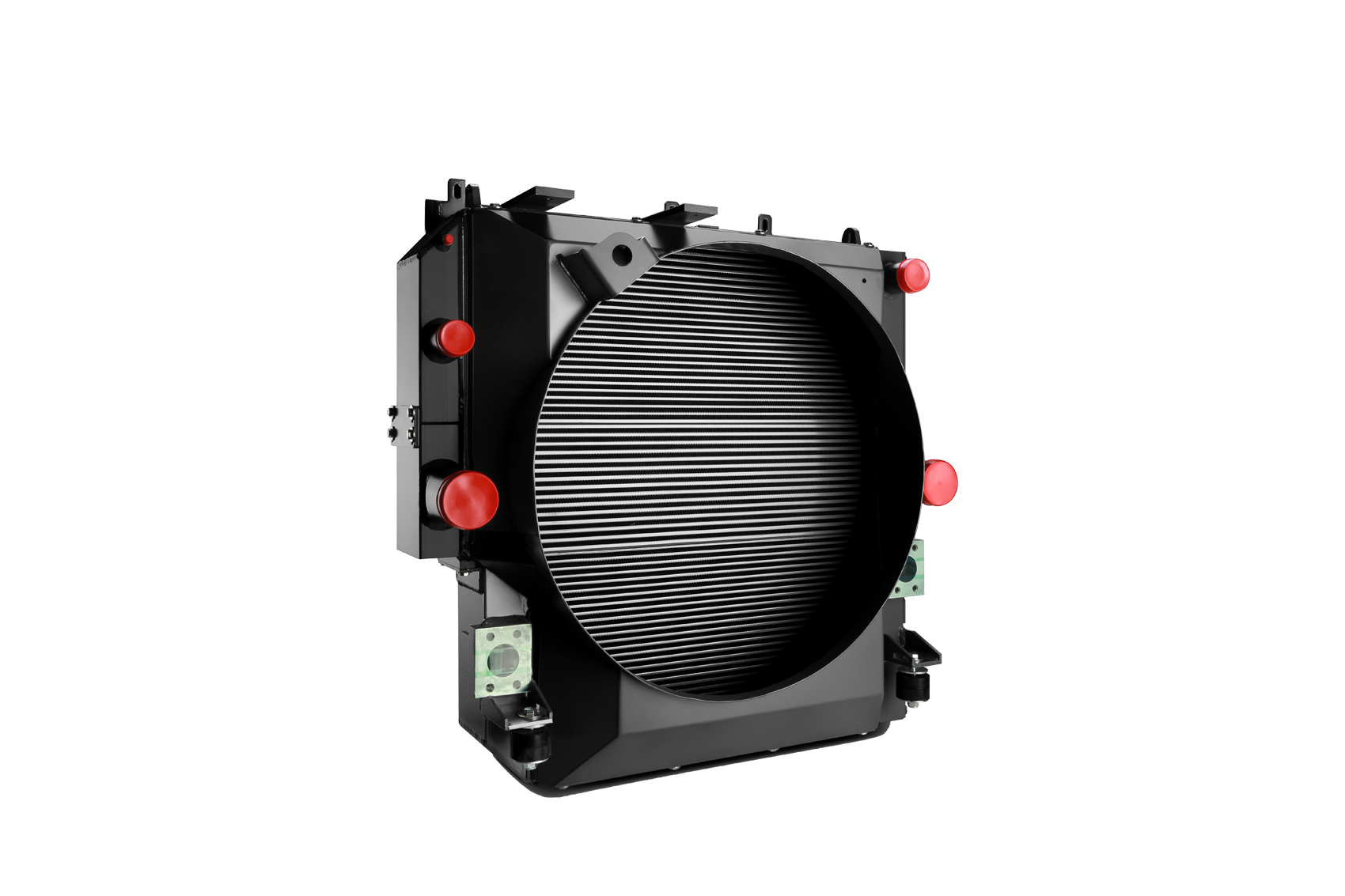

Professional manufacturer of medium and high pressure plate fin heat exchangers

Professional manufacturer of medium and high pressure plate fin heat exchangers

Wuxi Zhongbo Cryogenic Engineering Co., Ltd. is located beside the scenic the Taihu Lake , adjacent to Xiyi Expressway. The company covers an area of 40,000 square meters. It was founded in 2006, formerly known as Wuxi Zhongbo Heat Exchanger Co., Ltd., with a registered capital of 72 million yuan.

-

2006

Establishment time

-

40,000 ㎡

Cover an area

-

30,000 +

Annual sales revenue (10,000 yuan)

-

5,000 +

Serve customers

PRODUCT

PRODUCT

Our main business is the development, design, manufacturing, and sales of cryogenic technology equipment

APPLICATION AREA

/

CAPACITY

/

PARTNER

NEWS

ZHONGBO SERVICES

-

01

-

- Using HYSYS software, it supports data transmission through integration with user systems, facilitating process verification

-

02

-

- Optimize the arrangement and structure of heat exchanger channels, avoid hidden dangers such as thermal shock, extend service life, and help customers improve efficiency

-

03

-

- Advanced brazing manufacturing technology ensures the reliability of high-pressure welding and adapts to relatively harsh working conditions

-

04

-

- Adopting strict physical property equation optimization design, energy consumption is reduced by reducing pressure drop and resistance, balancing channel temperature difference, and ensuring long-term stable operation of heat exchange equipment

-

05

-

- Two phase flow mixing technology ensures uniform mixing of gas-liquid, reduces energy consumption and improves heat transfer performance, avoiding thermal shock stress damage (design life>20 years)

-

06

- Provide design stress and nozzle load analysis to ensure reliable resistance of heat exchange equipment to stress impact during start-up and shutdown conditions

-

07

-

- Independently designed and completed the pressure alternating fatigue test of the heat exchanger, solving the key problem of the heat exchanger in energy storage projects

-

08

-

- Zhongbo after-sales service responds within 36 hours, arrives at the site to handle heat exchanger channel issues, and provides technical support and repair solutions

-

Tel

+86 0510-85589898

+86 0510-85586011

-

Email

sales@wxzhongbo.com

-

WeChat

Scan

-

Top

中文

中文

MORE

MORE

R&D personnel

R&D personnel

Design software

Design software

Research and design of new high pressure fins

Research and design of new high pressure fins

Monthly production capacity reaches 680 tons

Monthly production capacity reaches 680 tons

Senior technical team

Senior technical team

Standardized operation throughout the entire process

Standardized operation throughout the entire process